Industrial Fasteners

The Beginner's Guide to Industrial Fasteners

Let’s dive into the world of industrial fasteners. They might not be the first thing that comes to mind when you hear the terms manufacturing or engineering, but these small components are actually responsible for holding everything together. If you’ve ever wondered what makes a fastener tick—or why it matters which one you use—you’ve come to the right place. This guide breaks it all down, providing an overview of the types of fasteners used every day.

What Are Industrial Fasteners?

So, what exactly are industrial fasteners? They’re the connectors that hold everything together, from bridges to engines. Think bolts, nuts, screws, washers, and rivets—basically, they’re the building blocks of any solid structure. Without them, we'd have a whole lot of loose parts!

Used in manufacturing, construction and engineering, these fasteners are typically made from materials like steel, stainless steel, and aluminium. They’re chosen for their strength, durability and their ability to withstand extreme conditions. Whether it's holding the frame of a building or the engine of a jet, industrial fasteners do all the heavy lifting (in a very literal sense).

Types of Industrial Fasteners

Now, let’s get into the nitty-gritty of the different types of fasteners. Each one has a unique role to play, depending on your project. Here’s a quick breakdown:

In the world of manufacturing, choosing the right fastener is more than just a technical decision—it’s a strategic one. It’s about ensuring your project runs smoothly, safely, and efficiently. The right fastener can make all the difference when it comes to performance, durability, and cost-effectiveness. So, don’t skimp on quality.

Ready to make the right choice for your project? Browse the options of industrial fasteners on this article to help achieve the best results for your manufacturing needs, and get in touch for expert advice regarding the best fastener solutions. Click here for Aerobolt's Handy general fastener downloadable pdf.

Are you looking for a supplier to meet your fastening needs? You will find Aerobolt's general fastener inventory would have to be Sydney's best kept secret. We have over 30 years’ experience in supplying the very best fastening and assembly solutions from industry leading manufacturers with brands you know and trust.

Bolt Types

Bolts are the big players in fastening. These threaded heroes are used in everything from cars to bridges, typically paired with a nut to form a secure connection. Bolts are the most common type of fasteners. They are usually used to hold two unthreaded components together. A bolt has external male threads on one end and a hexagonal head on the other. The bolt is normally fastened with a nut or a nutsert on the other end. There are many different types of bolts to choose from. Each type provides some trade-offs. Let’s take a look at some popular bolts types.

Hex Head Bolts

Hex head bolts have the bolt head in the shape of a hexagon and can be tightened easily using a spanner. The six sides offer a good granularity of angles to approach the bolt, this is especially important for bolts fastened in difficult to reach spots. Hex head bolts can have the machine thread extend halfway up their shaft or all the way up to the bolt head. Partially threaded bolts deliver a higher shearing capacity. Hex head bolts are extensively used in machinery as they are easy to assemble and disassemble.

Huck Bolts

A Huck Bolt is a two-piece fastener that consists of a hardened steel pin and a softer steel collar, that are swaged into the grooves of the pin to become a single entity with superior vibration resistance, compared to most other fastener types. Huck bolts are rapid industrial fasteners due to their quick installation, they are a hassle-free pin collar combo commonly used in the fabrication of truck, truck trailers, ute trays, ute canopy bodies, emergency vehicles and other applications where a vibration resistance fastener is critical.

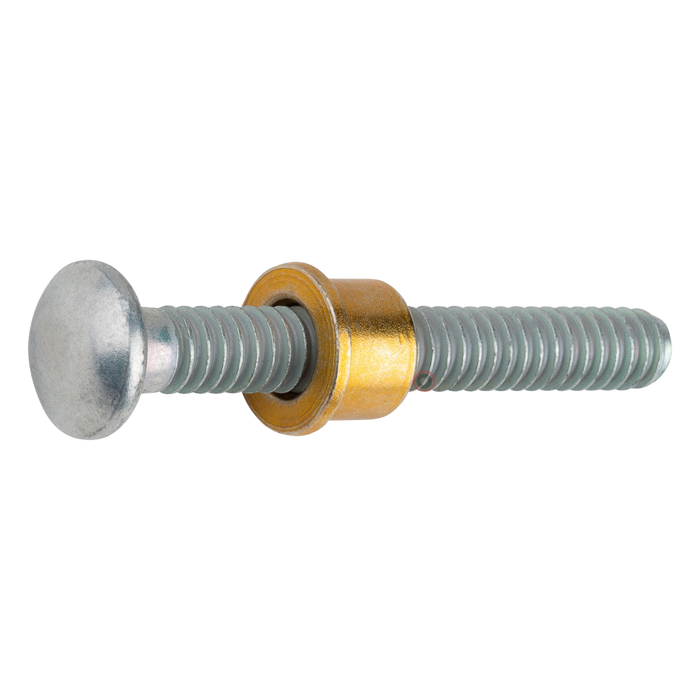

Coach Bolts

Coach or carrige bolts have a convex steel head followed by a square neck base and a threaded pin. This bolt type is mostly used to fasten timber elements. It's designed to fit the square neck into a wood piece through pressure. This feature gives coach bolts the self-locking element. The bolt is hammered gradually while securing the other side with a nut. Creating a pocket for the square neck in the timber, holding the bolt firmly in place.

Socket head bolts

Socket head bolts are a type of fastener that feature a head with a hexagonal recess for an Allen key or hex-shape socket tool to tighten them. Also known as a machine bolt or machine screw and come in a wide range of head styles including pan, dome, countersunk and more. These fasteners differ from hex head or coach bolt option because their head is specifically designed to engage with a drive tool for their installation, such as a slotted, Phillips, or socket head.

Common Applications Include:

-

Machinery Assembly: Joining parts in industrial equipment and mechanical systems.

-

Electronics: Assembling delicate components in electronics, electrical boards and more.

-

Automotive: Fastening parts in cars, such as license plates or headlights.

-

Furniture: Securing hardware and assembling modular kitchens and other furniture.

Nuts

Nuts are the little sidekicks to bolts, providing the threaded connection that keeps parts in place. From hexagonal to wing nuts, they come in all shapes and sizes for different jobs. A nut is a fastener with an internal thread. It is used in conjunction with a mating bolt of the same size.

Hex Nuts

The most common of them all, these are cheap and easy to assemble with a spanner. Hex nuts are six-sided fasteners with an internal thread, designed to secure bolts or screws in mechanical assemblies. Available in various materials like steel, stainless steel, or brass, they come in standard sizes (e.g. M6, M8 etc) and thread types (metric or imperial). Used in construction, automotive, and machinery, hex nuts provide strong, reliable joints and are often paired with washers for added stability.

Nylon Lock Nuts

Nylon lock nuts are similar to hex nuts in their build but have an extra collar to accommodate a nylon ring. The ring pushes into the bolt’s thread to prevent loosening of the nut. These six-sided fasteners with internal threads are typically made from steel or stainless steel and come in standard metric or imperial sizes. Widely used in automotive, machinery, and vibrating equipment, they offer enhanced security against loosening due to vibration.

Nutserts and Rivnuts

Nutsert or rivnuts are a blind threaded inserts designed to provide load bearing thread in thin sheet materials. They are fundamentally a nut that attaches onto a steel sheet surface for bolting purposes, when a simple hole opening is unsuitable. Ideal for punched or drilled holes, they can be installed at any stage of the production, even after finish coat is applied. They are an easy rapid industrial faastener solution that requires a tool for their installation.

Washers

Washers might seem like a small detail, but they really do help in distributing pressure evenly, protecting surfaces and preventing damage. Washers are small, circular, metal discs in the shape of a ring. They are a type of fastener that is normally used in conjunction with bolts and nuts. They are typically placed under nuts and serves multiple functions such as:

- Alleviation of friction.

- Even distribution of pressure from nut/bolt.

- Isolation of components.

Standard Washers

Standard washers, made for general use, are designed for even load distribution and diminishing hole size differences. These thin, flat, circular metal discs have a central hole to fit bolts or screws. Typically made from steel, stainless steel, or brass, they come in various sizes to match fastener dimensions. Used in construction, automotive, and machinery, standard washers prevent surface damage, reduce wear, and ensure stable, secure connections when paired with nuts and bolts.

Large flange washers

Large flange washers feature a standard inner diameter and an oversized outer diameter to distribute the load over a wider area. These flat, circular washers, typically made from steel or stainless steel, are designed for standard bolt or machine screw sizes. Their broad surface prevents pull-through and surface damage, making them ideal for thin or soft materials like sheet metal in automotive, construction, and fabrication applications. Large flange washers enhance fastening stability by evenly spreading stress, improving durability and preventing deformation in delicate materials.

Spring washer

Spring washers, engineered with a split or wavy design, provide axial flexibility, acting like a spring to maintain tension in bolted joints. Typically made from steel or stainless steel, they fit standard bolt or screw sizes. Their elastic properties counteract loosening caused by vibration or thermal expansion, making them essential in automotive, machinery, and industrial applications. Spring washers ensure reliable fastening by maintaining consistent pressure, enhancing joint integrity under dynamic loads.

External tooth lock washer

External tooth lock washers have teeth that extend radially outward at a small angle. When placed between the nut and substrate, after they are tightened, they bite into the bearing surface, holding the fastener in place. Typically made from steel or stainless steel, these washers fit standard bolt or screw sizes and are ideal for soft materials like plastic or aluminum. Used in automotive, electronics, and machinery, external tooth lock washers prevent loosening by enhancing grip, ensuring secure, reliable fastening..

Internal tooth lock washer

Internal tooth lock washers have teeth that extend radially inward, biting into the fastener when tightened to prevent relative motion. They also assist with absorbing shock and vibration. Typically made from steel or stainless steel, these washers fit standard bolt or screw sizes and are ideal for applications requiring secure fastening. Common in electronics, appliances, and machinery, internal tooth lock washers ensure reliable joints by enhancing grip and maintaining stability under dynamic conditions.

Split washer

Split washers, resembling a flat washer with a single cut and offset ends, create tension when compressed. The bent ends dig into mating surfaces, resisting loosening. Made from steel or stainless steel for standard bolt or screw sizes, they’re used in machinery, construction, and heavy equipment. Split washers ensure secure fastening by maintaining tension and grip, preventing loosening under vibration or heavy loads.

Finishing washer

Finishing washers, also known as countersunk washers, are designed for use with countersunk screws. These shallow, cup-shaped washers have a recessed center that aligns with the screw head, creating a flush, polished appearance. Typically made from steel, stainless steel, or brass, they fit standard screw sizes. Ideal for furniture, cabinetry, and decorative applications, finishing washers distribute load evenly, protect surfaces, and enhance aesthetics by providing a clean, professional look to fastened joints.

Screws

Screws are smaller and often more versatile than bolts. To be clear about the difference between a bolt and a screw; a bolt passes through an unthreaded hole and is secured by a nut on the other side. Whilst a screw is inserted into the material by cutting into the material. Bolts are designed for heavy-duty applications requiring strong clamping force, whereas screws are more versatile, creating their own threads in light weight materials.

Self-Drilling Screws

Self-drilling screws do not require a pre-drilled hole to be installed. They feature a distinctive drill-bit-like point with cutting flutes that bore through steel or timber, whilst the threads engage the material to create a secure connection. The material used for the screw is harder than the objects to be joined. The screw tip is available in different shapes but generally, a small taper is provided with a notched tip so that the screw can easily create space for itself in the substrate while being turned.

Self tapping Screws

Self tapping screws are engineered with threads that cut and form their own mating thread into the base material. Often confused with self-drilling screws, self tappers require a pre-drilled pilot hole for accurate installation, especially in metal substrates. Available in pan head, countersunk, undercut countersunk, and mushroom head styles, available in hardened zinc-plated steel, 304 stainless, and marine-grade 316 stainless for high corrosion resistance. Suitable for fixing into sheet metal, aluminium, steel framing, timber battens, PVC, and wall plugs, they are a go-to solution for both trades and DIY.

Rivets

Blind pop rivets are the unsung heroes of high-strength fastening. A rapid industrial fastener that is commonly used in aerospace and automotive industries, they’re perfect for permanent, secure connections. Rivets are permanent fasteners that require an tool for their quick installation and used to secure many different types of materials.

They are lightweight and offer great support against shearing forces. The presence of a head at each end enables the rivet to support axial loads up to a certain extent. A special tool known as a rivet gun (or a riveter or a pop riveter) is used for installing rivets. Holes do not need threads when rivets are to be installed.

Unlike threaded fasteners, rivets create a permanent joint and cannot be removed and reused. Rivets offer an excellent strength-to-weight ratio. They are also easier to inspect (compared to welded joints). A visual check is sufficient for inspection (unlike in welding, where special tools are needed to inspect joint integrity).

Each of these fasteners has a specific role, making them perfect for different applications. Choosing the right one can save you time, money, and potential headaches down the line. We have a wide range of rivets covering high performing structural rivets throught to general purpose pop rivets. When it comes to rivets you will find Aerobolt has a one stop shop destination at Rivet Dept.

What is the Fastener Industry?

The fastener industry is bigger than you might think. It’s responsible for manufacturing the components that hold together nearly every product or structure on the planet. From aerospace to automotive to construction, the fastener industry keeps the world turning (literally).

Innovation in materials and manufacturing techniques means faster, stronger, and more reliable fasteners are always coming to market. It’s a high-stakes, fast-paced industry where precision is key, and quality is non-negotiable.

Key Players in the Fastener Industry

Just like any industry, the fastener world has its heavyweights. Companies like Stanley Black & Decker®, Hilti®, and Huck Aerobolt (us) are top tier specialist fastener suppliers, setting the standards for quality, performance, and innovation. Huck Aerobolt, in particular, is a leader in high-performance rapid fasteners, especially when it comes to industries like motor body fabrication, manufacturing, mining, transportation, and construction.

How Do Industrial Fasteners Impact Manufacturing Efficiency?

It’s no secret that choosing the right fastener can have a major impact on manufacturing efficiency. The right industrial fasteners don't just hold things together—they can improve assembly speed, reduce the need for maintenance, and ensure the final product is built to last. In short, the right fastener helps manufacturers save time and money. Choosing poorly, on the other hand, can lead to assembly delays, defective products, and costly rework. So, the right fastener is a small investment that pays off big time.

The Role of Rapid Industrial Fasteners in Manufacturing

Enter rapid industrial fasteners—the speedsters of the fastener world. These fasteners are designed to reduce downtime and speed up the manufacturing process. Think of them as the pit crew of the industrial world, getting everything put together quickly and efficiently. By using quick-install fasteners, manufacturers can save valuable time and get products out the door faster. Aerobolt has a comprehensive range of rapid industrial fasteners from the wide range of lock bolts with the Huck® fasteners and structural rivets with popular Huck® rivet Magna-Lok®, Allok® structural rivets and an all weather-proof Tri Bulb structural rivet.

Why Choose Huck Aerobolt for Your Fastening Needs?

Huck Aerobolt isn’t just another fastener supplier. We’re a trusted partner in high-performance fastening solutions. Our fasteners are built to last, designed to withstand the harshest conditions, and engineered to provide maximum reliability in even the toughest applications.

We’ve got decades of experience in the fastener industry, and we know that quality, durability, and performance matter. Huck Aerobolt fasteners are the go-to choice for industries that demand the best.

Benefits of Huck Aerobolt Fasteners for Industrial Applications

Durability: Huck Aerobolt fasteners are designed to perform in the toughest conditions. Whether it’s extreme temperatures, high pressure, or heavy loads, our fasteners are built to last.

Efficiency: Fast installation means less downtime and more productivity. Huck Aerobolt fasteners are easy to install, saving you time and money on the job site.

Versatility: Our range of fasteners is ideal for a variety of applications, from heavy machinery to construction, automotive, and more. Whatever your needs, Huck Aerobolt has the solution.

With Huck Aerobolt, you’re not just getting fasteners—you’re getting a partner that’s committed to the success of your projects.

The Importance of Choosing the Right Industrial Fastener

Selecting the right industrial fastener is more than just a technical decision; it’s a strategic one that impacts the safety, efficiency, and longevity of your projects. At Huck Aerobolt, we understand the stakes and are here to guide you every step of the way. With our extensive range of high-performance fasteners and decades of industry expertise, we’re more than just a supplier; we’re your trusted partner in achieving flawless results.