Rivet Nut Types Explained: Nutserts & Rivnuts Guide

A Users Guide to the Different Rivet Nut Options.

Rivet nut is a type of fastener that combines the functionality of a rivet and a nut into a single, simple to use fastener. Also known as a nutsert or rivnut; in essence they are an internally threaded nut insert that can be placed onto numerous surface types. They facilitate a bolt where a stand alone one would fail because their clamping force would distort the material. Commonly used by manufacturers of tubular furniture, switchboards, electrical appliances, and so much more. Rivet nuts are available in steel, stainless-steel or aluminuim so there is bound to be a material to suit. Their installation is easy with a nutsert tool which compresses the fastener onto material by collaping the body and creating a blindside flange that holds the nut to the material with a permanent thread. Clever Huh!

Rivet nuts are readily available in metric sizes M3, M4, M5, M6, M8, M10 and M12 plus select imperial rivet nut sizes; 3/16',1/4'/, 5/16', and 3/8'. The measurements here relate to internal thread size and not the body's diameter. Our data sheets include body diameter, drill hole size and other information. Advantages with rivet nuts are numerous; just like pop rivets they are a blind fastener, this means they can be installed from one side. No need to stretch to the blind side, or coordinate with a second person to have access to the other side. Other than our wide range of rivets nut options, we are big on nutsert guns to suit your application, including air, cordless, and manual rivnut ratchet tools. Plus the repair and rental of nutsert tools. When considering rivet nuts, think of Aerobolt®.

Key features of rivet nuts:

Rivet nuts offer a number of advantages that make them suitable for 101 applications where a blind rivet won’t work including appliances, automotive manufacturing, office furniture, playground equipment, solar installations, electronics, boats, pools and hot tubs, military equipment, and even bicycles.

- Blind installation: Rivet nuts can be installed from one side of the material, making them useful for closed sections like tubing or where access to the other side is limited.

- Threaded insert: They provide a strong permanent internal thread in materials that are often too thin to support a threaded fastener like a bolt & nut combo or a machine screw.

- Versatile applications: Commonly used in automotive, aerospace, appliances, furniture assembly, marine, playground, solar installation, military among other industries.

Rivet Nut Types.

Rivet nuts are more versatile than self-tapping screws or pressed inserts. They are available in steel, stainless steel, aluminium, and more. There are two body variations – either open ended where the bolt can protrude through the rivet nut without obstruction, or closed end type. Closed end type rivet nuts are ideal if you’re looking for a sealed end, providing an effective option to avoid the ingress of water and or dust.

Nutsert xtralok®.

The Xtralok® nutserts has numerous features that distinguish it from other round nutserts including a knurl texture body that locks into the host material, thick walls that prevent thread distortion, a low-profile wide flange for a near flush installation and they have up to 50% more material grip range than most competitor products.

Half-Hex Nutserts.

Half-Hex nutserts provide all the benefits of the Nutsert Xtralok® only better with higher torque resistance to unscrewing and pulling out. Ideal in punched hex shape holes. Often called hex inserts, hexserts, hex threaded inserts etc. they are ideal for applications where failure is not an option.

Full-Hex Nutsert.

At Aerobolt® we regard the Full-Hex Nutsert as the "high strength Hex nutserts" because the full hex-shaped nutsert provides even better twist resistance than both the Nutsert Xtralok® and the Half-Hex nutsert. The Full-Hex nutsert works similar to other types in that the tool collapes the nut, creating a backside flange that holds the nut to the material.

Smooth Body Rivnut.

This Rivnut® option should be your first choice when seeking to drill a small hole size or you are working close to the edge of the parent material. A low-cost rivet nut choice to insert a load-bearing thread into weak or thin-gauge material. Predominantly with a countersunk profile with a lead-in chamfer for easy insertion.

Plus Nuts.

Plus Nuts are ideal for plastics, fiberglass and thin steel sheeting, a load bearing captive solution for lightweight material. Offering a greater material grip range than other types of rivet nuts, along with a better tolerance of oversized holes. Often referred to as the multi-grip rivet nut or cross nut because when installed the blind side anchor looks similar to a Byzantine cross.

Jack Nuts.

Jack Nut or J Nuts threaded inserts provide a captive nut for non-load bearing applications. Upon installation, the slotted sleeves collapses and expands to create anchor blades that gently grips the mounting surface to provide a permanant reusable anchor for a set screw or bolt. For load bearing solution refer to Plus Nuts.

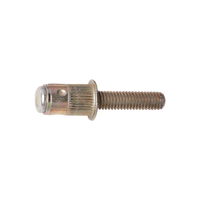

Threaded Studs.

Threaded Studs, rivbolt or rivet bolt are just some of the unusal terms to describe these clever components that provide a protruding threat for attachments. A screw-on fastener to be attached to thin steel sheeting. Their installation is similar to a captive nutsert however with this item you have a protruding thread instead of an opening. An economical alternative to weld-studs without the expensive tools or workplace safety issues associated with these specialised fasteners.

Well Nuts.

Well nuts are fundamentally a rubber bush with a concealed brass nut at one end. They have a flange on one side with a barrel body that you inserted into a matching size hole. Well nuts are an ideal option for weatherproofing holes or isolating vibration. Also referred to as a rawl nut, or a rub nuts, either way Aerobolt® has a wide range readliy available covering a range of different internal thread sizes including M3, M4, M5, M6, and M8 in different lengths.

Threaded Inserts for Plastic.

The A-W threaded insert can be installed in numerous material types from plastic to plywood. They work differently from others because they expand into the material rather than outside. The diagonal knurled treaded insert can be installed in a comprehensive range of material softer than itself and thicker than 16mm. Providing a sturdy internal thread for bolting applications with great pull out resistance.

Threaded Inserts for Timber.

Wide range of threaded inserts for timber, chipboard and MDF. Your one stop shop for threaded inserts for all your woodwork applications including, timber T-Nuts, Tee Nuts, Flange Timber Inserts and non-flange skein nuts. When seeking rivet nut type fastener for timber applications you can't go past Aerobolt® for range and service.

Rivet Nut Summary.

A rivet nut is an expanding nut that attaches onto a surface for bolting purposes, where a simple hole opening is not possible because the material is too thin to hold a bolt or a screw. They are ideal for punched or drilled holes and can be installed at any stage of the production, even after finish coat is applied. The ideal solution that requires a nutsert gun or a rivnut tool. Here at Aerobolt® we are the rivet nut experts and can assist in making your selection easy with a big range of rivet nut types through to nutsert tools. Should you require any assistance with selection please don't hesitate to contact us 02 9755 3747 or go to contact us.