Huck Bolts Explained: Benefits & How They Work

Understanding Huck bolts & how they work!

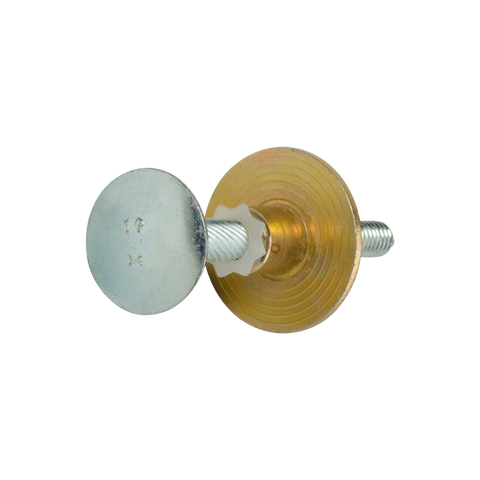

Huck bolts are fundamentally a two-piece pin & collar combo where the collar sits over the pin and is compressed into the pin's grooves via a designated tool. This makes the two-piece Huck® combo an integrated one-piece entity after installation. Huck® Bolts are designed to provide a permanent, vibration-resistant hassle-free solution for numerous applications. Their high strength means they are well suited to applications where the joint is just as important as the structure. They assist in lowering production costs by faster installations compared to other fastener types, whilst being a clean and safe alternative to welding and a better more permanent option than a standard bolt and nut.

There are numerous types of Huck® bolts to suit a wide range of applications, from thin sheet fabrication through to the the manufacture of the cranes associated with the loading and unloading of shipping containers. In today's blog we will be reviewing the popular standard diameter Huck Bolt MG, the large diameter C50L, and the specialty lock bolt the Hucktainer®. Huck bolts were developed to solve the problem associated with loosening fasteners in continuous vibration application. This was resolved in 1944 by Louis C. Huck who sketched the first vibration-resistant lock bolt, which went on to become the world famous Huck bolt. Read more about the History of Huck.

What are the key benefits of Huck Bolts?

Huck bolt offer numerous benefits over other fastening methods including quick installs, easy inspections, good appearances and high-durability.

- Improved productivity with faster installations: Huck bolts are placed in seconds.

- High shear & tensile strength, making them ideal in critical applications.

- Vibration & weather resistance solution, once swaged they will never loosen.

- Easy to use Huck guns, that come in a choice of air, cordless, or hydraulics.

- Quick inspections are sufficient to ensure correct installations.

What are the main Huck Bolts types?

Huck makes numerous different type of Huck bolts of varies diameter sizes and materials. The 3 main Huck Bolt options are; Huck Bolt Magna-Grip®, HuckBolt® C50L and Lock Bolt Hucktainer®.

The standard diameter Huck Bolt. In applications where material thicknesses can vary, the Huck Bolt "Magna-Grip®" with its flexible material grip range is the ideal fastener. This Huck bolt is renowned for its superior vibration resistance and neat appearance. Magna-Grips® have a starting pin diameter of 4.8 mm (3/16") through 9.5 mm (3/8"), click here if you want to convert imperial to metric. Huck Bolt MG are often used in the fabrication of trucks, truck trailers, ute trays, ute canopy bodies, emergency vehicles and numerous other fabricated products, where a vibration resistance fastener is critical to the application.

The C50L is a large diameter bolt that has defined Huck for over 50 years. It is a heavy-duty lock bolt that has faithfully served Australia's heavy engineering sector with its great clamping power in numerous critical applications including Sydney’s Harbour Bridge. The C50L fastener has a starting diameter size of 12.7mm (1/2") through to 28.6mm (1-1/8"), making it the perfect large diameter lock bolt for mining equipment, truck chassis, steel bridges, and railway track applications.

The Hucktainer was designed for fiberglass reinforced plywood (FRP). It is a specialty lock bolt fastener that avoids crushing FRP panels and provides a low-profile fastener on both sides of the application. Hucktainers feature a heavy zinc plating that resists corrosion and rust stains, making them ideal for attaching highly used components such as hinges, latches, and locks on truck doors.

Three Things to Know About Huck Bolts.

- Superior and permanent alternative to welding and nuts & bolts.

- Extremely high vibration resistance with no follow-up maintenance required.

- Fast & easy installations. Minimal training & faster installation than nuts & bolts and welding.

5 Reasons to Use Huck Bolts Over Welding.

For many years, welding was the only way to ensure the integrity of joints in demanding load-bearing or high-vibration applications. However, the lack of regulation covering steel manufacturing and fabrication has become a quality issue as the government has eradicated the regulations that mandated compliance to Australian Standards. Huck bolts overcome numerous quality issues associated with welding and the reasons to use Huck bolts over welding are many.

- Huck bolts are safe compared to welding. Welding comes with many health issues, along with spark risks, as numerous fires have been started by random sparks.

- Fast and easy installations that save you money. Installing Huck bolts requires minimal training, unlike welding. Surface preparation is not critical with Huck bolts and human error is reduced.

- Huck bolts are immune from the issues of heat-affected zones (HAZ). This can cause material strength issues whereas Huck bolts avoid thermal expansion issues.

- Regular Inspections. Huck bolts allow for quick inspection, whereas welds are difficult to inspect and the inspections often require expensive equipment.

- Easier to modify. Unlike welding, you can easily remove and rework a Huck bolt. Welding on the other hand is extremely difficult and requires a trained operator to rework once the weld is set.

Huck Bolt Installation Sequence.

Frequently asked Huck bolt questions.

How to remove a Huck bolt?

The standard Huck bolt Magna-Grip can easily be removed by using a cutting disk to remove the head or the collar by gliding under the base. If access is an issue, consider drilling them by centre punching and then drilling with a bit just a little larger than the shank until the head or collar spins off. A small pilot hole deep enough to get past the head helps.

If you wish to remove a HuckBolt C50L you have the option to purchase a Huck collar cutter, click here to learn more.

Where are Huck bolts used?

Huck Bolt fasteners are used in the fabrication of ute trays, ute canopy bodies, trucks, truck trailers, emergency & utlities vehicles, steel bridges, railway tracks, turn-outs and crossings, passenger & freight trains, mineral crushing equipment, agricultural & silo equipment, and many other sheet metal applications where vibration is present.

What is a Huck machine?

A Huck machine is essentially a hydraulic power unit for the installation of oversize C50L Huck bolts. When installing C50L HuckBolts you will need this unit along with a Huck hydraulic gun, nose assembly and a genuine Huck® hose to install the Huck Bolt C50L range.

What’s the difference between Huck Bolt and Monobolt®?

Essentially a Huck Bolt and a Monobolt® are both fasteners that are used to join two or more materials together. A Huck bolt is a two-piece fastener whilst a Monobolt® is a one-piece rivet.

A Huck bolt is a two-part pin & collar assembly that becomes a single entity through a mechanical process. This occurs when a tool applies pressure to the collar and forces it into the grooves of the Huck bolt pin. See how Huck Bolts work here.

A Monobolt® is a single fastener that installs like a standard rivet via a tool. Monobolt® is a trademark for a structural rivet, a rivet is composed of two components, a metal tube (body) & pin (mandrel). The pin is normally longer than the tube and designed to be pulled up through the tube whilst enlarging it in the process. This results in the rivet clamping the material. See how Huck structural rivets work here.

Can I get coloured Huck Bolts?

Yes, Aerobolt offers painted Huck bolts. They cost a little extra compared to the mill (raw) finish and are available in a wide range of colours. Refer to the Colorbond ® colour chart for selection.

What is the advantage of Huck Bolt?

Huck Bolts never loosen. Threaded bolt & nut have been around for centuries and are useful for a wide range of applications. Their drawback is that nuts and bolts can become loose over time, especially if they are being used in high-stress applications or where continuous vibration is an issue. The Huck bolt was developed by Louis C. Huck in the 1940's to solve this problem by completely redesigning the bolt as a two-piece fastener that uses metal-on-metal contact to secure it in place as a permanent bond.

What other Huck bolt options are there?

Huck has a comprehensive range of lock bolts other than the popular Huck Bolt Magna-Grip, this includes.

The BobTail® is a corrosion-resistant lockbolt that is new to Australia and can be installed using a lightweight tool. This Huck is available in steel, stainless steel, and aluminium. Engineered to meet the challenges of a wide range of assembly applications, BobTails offer safe, quiet, swaged-on installation technology in a unique, pintail-less design.

Huck bolt 360°, the most advanced bolt & nut combo on the market. Easy to install the 360° nut & bolt is engineered to be hassle free and resistant to vibration, even under extreme conditions. The latest addition to the Huck bolt family is the most advanced nut and bolt fastener combo on the market.

Huck Breaker Bolt. This is a unique Huck bolt solution to loosening plates in rotary coal breakers, with a square head, tapered shank, uni-directional washer, and a high stand -off collar. Loose fasteners are now no longer a problem.

Why has my Huck Bolt failed?

Huck bolts rarely fail, we have noticed generic lock bolts failing with some people mistakenly believe they have purchased Huck bolts. In reality they have purchased a Huck bolt alternative without being advised this is not a Huck brand lock bolt. There are a couple of reasons your Huck bolt has failed. The issue could be a dodgy lock bolt or an installation issue. Either way we offer a wide range of technical services to right the wrong, including Huck bolt lab testing services. We have teamed up with a NATA approved lab, that undertakes laboratory lock bolt testing services. Should you have a Huck bolt failure, let us know so we can review your application and or have your lock bolts sent to a NATA approved lab for lockbolt laboratory testing.

Do I need a special tool to install a Huck Bolt?

Yes, you will need to purchase or hire a Huck gun. Go to Huck guns to view the range or tool hire.

Can you help with manufacturer's code MGLP-R8-E or MGPB-R8-10G?

Yes, we can help with Huck's product code, contact us for phone assistance. We have moved away from the manufacturers codes as there was little consistency between the Huck Bolt and Huck’s rivet range. For instance, in the Huck Bolt “Magna-Grip” range, the letter “E” represented the material aluminium, whilst in the Huck Rivet” Magnalok” range, the letter “B” is representive of aluminium and the "E" represents "Extra Grip Range". Go figure! We have simplified the product codes to minimise error, you will find our codes are easier to understand, for instance that the letter “A” represents the material aluminium, “S” for steel, “SS” for Stainless Steel and "E" has been retained for the representation of "Extra Grip Range".

How do you spell Huck?

English spelling can be somewhat challenging, you have to think about how words sound and then translate those sounds into print. Add to the mix remembering spelling rules — and recall the exceptions. Then consider different words that sound the same: Sent, cent, or scent? There, they’re, or their?

Huck; is one word that can be written with a couple of variations such as Huk, Hock or Hak, please don’t feel embarrassed by any misspelling.

What is a huck bolt used for?

Huck bolt fasteners are most often used in the manufacturer of special vehicles like Truck & trailer body builders, Emergency & utility vehicles, Ute trays canopy body building, Sheet metal fabrication, mining equipment, railways, trains, steel bridges and so much more.

Who makes Huck Structural rivets and Huckbolts?

Huck fasteners are manufactured by Howmet Aerospace in the USA.

Do you deliver Huck Bolts throughout Australia?

Yes, we can deliver Australia wide through our network team of courier companies. In Sydney we offer our customers same day delivery if you order before 10.00 am or next day delivery. Deliveries to regional New South Wales or major cities such as Melbourne, Brisbane including regional South-eastern Australia are either next day delivery or 2 days turnaround. We can also assist with freight to New Zealand and South East Asian countries. To read more click here.

THE BENEFITS OF HUCK BOLT SUMMARY.

Huck Bolts are a two piece pin & collar combo used in the fabrication of truck, truck trailers, ute trays, ute canopy bodies, emergency vehicles and numerous other steel fabrication applications where a vibration resistance fastener is critical to the application. At the conclusion of this blog, it is evident that Huck bolts play an important role in the fastener world and irrespective of the Huck bolt needed for your project, be assured that your project will end up as a successful one with the use of Huck bolts - call us on 02 9755 3747 or contact us for guidance.

AEROBOLT - AUSTRALIA’S #1 AUTHORISED HUCK DISTRIBUTOR. HUCK BOLTS, HUCK BLIND RIVETS AND HUCK GUNS

Since 1993 Aerobolt has been the leading authorised distributor of Huck bolts, Huck tool & Huck gun rental & repairs. As a full-line Authorised distributor, we receive factory direct prices and are Authorised to extend all aspects of Huck’s warranty.

Aerobolt personnel are trained to demonstrate and support Huck’s range and will be your liaison point for communications to Huck International during and after the warranty period on all products you purchased through us.

WHAT DOES IT MEAN TO BE APPROVED HUCK DISTRIBUTOR?

Aerobolt Australia Pty Ltd must meet certain requirements and are qualified to supply products, services, and support on behalf of the manufacturer. We have received product training and are always up to date with the latest products.

In short, being a Huck authorised distributor means the following:

We are authorised to and are selling genuine Huck bolts, rivets, and Huck guns. Comprehensive range covering the everyday items like Huck bolt Magna-Grips and the Huck rivet Magna-Loks to the hard-to-find spare part.

Provide the highest level of customer service and product knowledge. We work with Huck to ensure that you receive value and aim for the right application solution.

High standard of corporate & social governance, including environmental standards as Huck International. Being a Huck Authorised Distributor means we are Huck.

Copyright © 2025 Aerobolt Australia Pty Ltd. All rights reserved.