Tri-Fold vs Bulb-Tite Rivets: Which Is Better?

Bulb-Tite® V's TriFold rivets. Understanding the key rivet differences.

When does one select a Bulb-Tite® rivet over a Tri-Fold rivet? What's the difference? Does one rivet type have an advantage over the other? These are some of the questions our customers ask when seeking to understand the Tri-Fold rivet compared to the Bulb-Tite® Rivet. There are numerous rivet types on the market and selecting the right rivet can be a little complicated. In this blog we will investigate two of the most specialised rivet types on the market and look into the pros and cons of the Tri-Folding rivet & the Gesipa® Bulb-Tite® rivet.

These rivets are great for joining numerous lightweight material including plastics, fibreglass, composites, thin sheet metals and more. Both these rivets pull-up to form a blindside tri-star shape propeller anchor. The Gesipa® Bulb-Tite® rivet is a structural rivet that suits LOAD bearing applications involving lightweight material, whilst the Tri-fold rivet is a standard rivet that is suitable for NON-LOAD applications involving lightweight material.

These rivets suit lightweight material because they work differently to other rivet types as the clamping force is spread through the three anchor blades rather than concentrated in one spot. The propeller shape anchor provides excellent pull through resistance that you will not find with other typical rivets. Many people refer to these type of rivets as load spreading rivets or exploding rivets and are the go-to rivet for lightweight applications.

Some of the key benefits associated with rivets include:

- Blind side assembly means quick installations, as access to the rear is not required.

- Highly resilient, forming a mechanically activated permanent joining solution.

- Easy to use air, cordless, & manual rivet tools that require minimal know-how.

What is a Tri-Fold rivet?

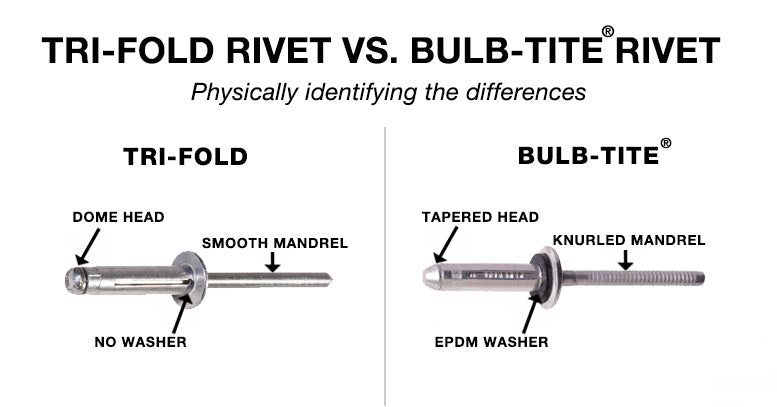

This rivet is an all-aluminium slotted body standard rivet which makes it suitable for lightweight applications, it forms a propeller shape anchor on the blind side of the material without damaging it. Tri-Fold rivets are also known as Bulbex®, Tri-Folding, and Bulb-Lite® rivets.

What is a Bulb-Tite® rivet?

Bulb-Tite® is also an all-aluminium slotted body rivet that creates a propeller shape blind-side anchor. Gesipa® Bulb-Tite® is classed as a structural rivet with the advantage of a washer under the setting head that combines with the anchor to provide a waterproof resistant joint. A structural rivet means this will have better shear and tensile installation values compared to a Tri-Fold. These rivets are also known as Huck-Tites, Tri-Bulb, or Klamp-Tite® and are suitable for motor body fabrication when the application involves composite materials like those associated with refrigerated or pantech trucks.

Select Bulb-Tite® rivets are also recommended and used in the installation of safety roof anchor points.

Bulb-Tite® rivets five main benefits.

Gesipa® Bulb-Tite® rivets have numerous benefits over the standard Tri Fold rivet inclding;

- Structural rivets; Bulbtite® is a structural rivet with higher shear and tensile installation values compared to Tri-Fold rivet. This makes them better suited in load-bearing situations when fastening plastics, fibreglass, thin steel sheets & other composite materials.

- Safety Roof Point Approved; Bulb-Tite® rivet with the product code - RV660-9-06W is the only rivet approved by the Occupational Safety & Health Administration for roof anchor points, including the fall arrest systems + the rope access systems.

- Weather & vibration resistance: Bulb-Tites® are virtually a waterproof rivet as they come with an EPDM washer under the head. This provides an excellent weather tight seal that is more resistant to vibration compared to a Tri-Fold rivet.

- Hard-To-Fasten Applications; Bulb-tite® rivets work well in materials where other fasteners fail. The folded legs individually conform to curved surfaces enabling fastening onto pipes, corrugations and other challenging shaped applications.

- Multi-Grip Range Capacity; Bulb-tite rivets can handle a wider variation in material thickness. This means fewer different rivet sizes may be required, resulting in reduced inventory requirements, simplified fastener selection and less likely operator error.

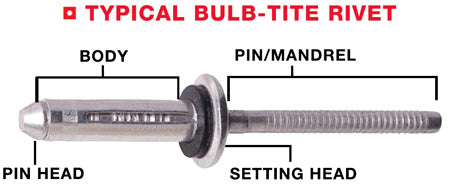

How to identify a Gesipa® Bulb-Tite® rivet?

Bulb-Tite® rivet V’s Tri-Fold rivet frequently asked questions.

What is a roof anchor point?

A roof anchor point is an assembled device that is installed on the roofs of buildings for contractors to attach harnesses, ropes and other equipment to prevent a fall mishap. A correctly installed safety point aims to provide protection from falling.

How do I install a Bulb-Tite® rivet correctly?

Installing a Gesipa® Bulb-Tite® rivet is simple with a little practice, pre drilling of holes is required. Load rivet’s pin tail section into rivet gun. Insert rivets body into hole and activate gun. Upon activation the head of the rivet is pushed against the outer surface of the tool, whilst the tool pulls up the central pin. As a result, the bottom portion or blindside of the rivet rivet body folds into three separate legs forming a large blind-side head. This creates a large bearing head that evenly distributes the high clamp force in soft, thin or brittle materials while providing high pull through resistance. Resulting in a larger surface in which the two materials are effectively fastened together.

When placing the Bulb-Tite you will need to provide sufficient blindside space for the body's anchor blades to stretch out correctly, otherwise the rivet will not install. See below for the recommended Bulb-Tite installation process.

Pre-drilling correct diameter hole.

Ensure the correct nose tip and or jaws.

Blind side Tri-Star anchor.

Bulb-Tite® Installation Process.

- Rivet body is inserted into the pre-drilled hole.

- Setting tool pulls the pin and pin head into the rivet body.

- Blind side anchor is formed and when breaking force is reached pin breaks at break notch.

- Blind rivet is set and clamps parts together. How easy is that!

The diagram below shows correct & incorrect Bulb-tite placement. Its important to have sufficient blind side space for the slotted body rivet to fold and bend in the propeller shape anchor blades.

How do Bulb-Tite® rivets work?

Bulb Tite structural rivets work a little differently to standard rivet, as there is an internal mechanism that locks a portion of the pin (mandrel) inside the rivet's body. This creates an additional layer of material that assists in increasing the rivets strength, whilst interlocking with the material and creating their inner strength. When installing a Bulb tite the slotted body folds and splits into a propeller shape blind–side anchor. The diagram below provides a four step overview of the process.

Which is the best rivet gun?

Selecting the correct rivet gun depends on several factors that relate to your specific requirements, rivet gun section is covered in the blog; Ultimate Guide to Rivet Guns.

How do I remove a Bulb-Tite® rivet?

Bulb-Tite® rivet removal is straight forward with the right tools. This requires the destruction of the rivet, and the best method is to drill it. You will need, a drill, drill bit, long nose pliers, & safety accessories such as glasses and gloves.

Steps: Use your safety glass & gloves before starting the drilling process. Place the drill bit against the rivets’ center pin and drill through the body at a low but steady speed. Once drilling is completed, pull the rivet off with your long nose pliers. How easy was that!

Can you assist me with Bulb-Tite® & Tri-Folding rivet selection?

Sure we can assist with rivet selection and so much more. We are Sydney's leading rivet supplier with a comprehensive range of general standard rivets plus industrial strength structural rivets including the sale, service and hire of rivet guns. You can reach us by either telephoning 02 9755 3747 or via the contact us page.

Do you deliver Bulb-Tite® & Tri-Folding rivets throughout Australia?

Yes, we can deliver Australia wide through our network team of courier companies. In Sydney we offer our customers same day delivery if you order before 10.00am or the next day. Deliveries to regional New South Wales or major Australian cities such as Melbourne, Brisbane including regional South Eastern Australia are either next day delivery or 2 days turnaround.

Bulb-Tite® rivet V’s Tri Fold rivet summary.

At the conclusion of this rivet type blog, it is evident that Bulb-Tite® rivets offer superior fastening capabilities compared to Tri-Fold rivets. Bulb-Tite® rivets are a strong & highly flexible option due to their superior strength and their extended material grip range. Seeking assistance to select the correct rivet type? Please don’t hesitate to contact us or call 02 9755 3747.

Aerobolt is the leading awar-winning wholesaler of standard rivets , structural rivets, Huck bolts, nutserts, rivnuts, adhesives & power tools, like nutsert tools and rivet guns including some popular cordless options.

Proudly, we are Australia's #1 Huck® Distributor of genuine Huck bolts and structural rivets plus the sale, service and hire of Huck guns and hydraulic power rigs.

Committed to providing a total supply solution with an award-winning customer service focus, your one-stop shop for technical know-how, supply of goods & tool hire through to the servicing of your equipment.