Magna-Lok Rivets. The Multi-Grip Huck Structural Rivet

Reviewing the MagnaLok® and other Huck® rivet types.

When it comes to the Huck® rivet range, you will find Australia's number 1 Huck® authorised distributor has the complete inventory including the Huck rivet Magna-Lok®, with its flexible material grip range, extra strong Magna-Bulb® and a combo of the two Hucklok®, along with numerous other rivets for specific applications. In today's blog we shall review Huck® rivets, covering their key features, and how Huck® rivets work. In challenging applications where vibration is an issue you can rely on Huck® fasteners to provide the strongest, and most reliable vibration-resistant solution. Huck® rivets lower production costs with reduced assembly times that compare favourably to welding or a bolt and nut combo. So in critical load bearing applications with proven results your first choice should always be Huck® structural rivets.

Structural rivets are great in heavy duty industrial applications where a strong secure vibration resistant solution is required for the fabrication of utility vehicles, utes, trucks, trains, truck trailers, and so much more. Magna-Lok® is the great all-rounder in the structural rivet category due to its versatility with material depth. This means one rivet can be very flexible with materials of varying depths. The Magna-Lok® has been lab tested against their nearest competitor rivet and outlasted them by almost 20 to 1. In fatigue tests, Huck structural rivet lasted 2 million cycles whilst the other lasted 100,000. Huck rivets have been engineered to be a fast and easy fastener to install with an internal locking system that mechanically locks the pin into the sleeve, whilst embracing the material at the same time. Who said you can't do two things at once? To read more about the Magna-Lok® rivet's lab performance click here.

Huck Structural Rivet Overview.

Huck® structural rivets are the smart secure solution to loosening and vibration challenges. Here we provide an overview of the popular Huck rivets, for a complete list + other types of heavy duty high strength rivets go to structural rivets.

Magna-Lok® Structural Rivets.

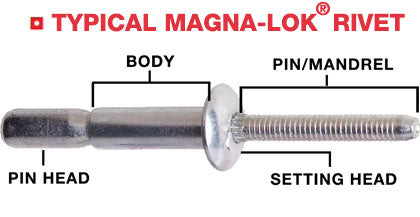

Magna-Lok® Rivet is a high performing locking rivet with extended material grip range, along with Huck's unique 360 degrees internal locking mechanism ensuring great resistance to vibration and moisture without damaging the surface. A high performing structural blind pop rivet that will reduce inventory, cost, and labour. Clever Huh!

Magna-Bulb Huck Rivets.

Magna-Bulb Rivets are renowned for their excellent shear & tensile strength among most other structural rivets on the market. When installed they produce a wide blind side footprint designed to spread the load, this is ideal in thin sheet fabrication.

Hucklok® Structural Rivet.

Hucklok® rivet is a double locking wide-grip range rivet, combining the extended grip range of the original Huck Magna-Lok and the strength of the Huck MagnaBulb rivet that has resulted in a rivet like no other, a rivet that locks material from both sides with excellent shear and pull-up force.

Huck-Tite Structural Rivet.

Huck-Tite is an all-aluminium structural rivet that pulls up into a propeller shape configuration; making them ideal for lightweight materials with a sealant under the head for weatherproofing the joint. How clever is Huck!

Huck Rivet BOM®.

Huck BOM® Rivets are often used as a replacement for welding, Huck BOM rivets are so strong that one BOM fastener does the work of up to four conventional fasteners. Ideal for military vehicles, high security fencing, and so much more.

How do Huck® structural rivets work?

Huck® structural rivets work differently to other standard rivets, as there is an internal mechanism that locks a portion of the pin (mandrel) inside the rivet's body. This creates an additional layer of material that assists in increasing the rivets strength.

When a Huck structural rivet is installed, the body changes in one of the following ways as it locks itself into place.

1. Broadening of the Body. (Magna-Lok® Rivets)

Body widens when the cap of the pin is pulled up, resulting in the body expanding against the material.

2. Body Compresses & Bulges. (Magna-Bulb® Rivets)

Rivet's body is compressed by the pin cap, causing it to bulge and form a bulb against the material.

3. Body Splits & Folds. (Huck-Tite® Rivets)

The slotted body folds and splits into a propeller shape blind–side anchor, ideal for lightweight material.

How do you install a Huck Magna-Lok structural rivet?

Installation of a structural rivet is similar to the standard rivet, the difference being the tool, as a structural rivet requires a Huck gun or a structural rivet gun, this is due to a standard rivet gun not having the correct jaws to install structural rivets.

Installing a structural rivet; pre drilling is required. Load rivet’s pin tail section into rivet gun. Insert rivets body into hole and activate gun. Upon activation the head of the rivet is pushed against the nose of the tool, whilst the tool pulls up the central pin. As a result, the body compresses, and expands on the blind side until it maxes out to approximately one and a half times the size of the original diameter. Resulting in a larger surface in which the two materials are effectively fastened together.

Which is the best structural rivet gun?

Selecting the correct rivet gun depends on the nature of the project + your specific requirements, below we cover the main rivet gun categories, along with their pros. & cons. At Aerobolt, we stock a wide range of popular brand rivet guns plus a few alternative options that we have rivet gun lab tested for quality and value. Our site has extensive information covering most tools for you to review. To discuss further, simply contact us.

Structural rivets guns are broken down to two main types

- Huck guns that install both structural rivets and Huck bolts (pin & collar).

- Rivet guns that install structural and or standard rivets. Note that not all rivet guns are capable of installing structural rivets. Here at Aerobolt, we have both options.

Huck Gun, air + cordless

These tools are suitable for the installation of both Huck bolts and Huck structural rivets with the simple changeover of a nose assembly (priced separately).

Air Huck Guns: For frequent installation, an air-powered Huck gun is the easiest choice for the job. Air powered Huck guns offer fast installations with consistent results. Some of the pros include: Easy to use, economical (cost saving compared to cordless), and no physical exertion required. They will also install to a set pressure / stroke. Cons: Requires an air source such as a compressor, possibly limiting mobility and making remote use impractical.

Cordless Battery Huck guns: Cordless Huck guns run on battery power and provide incredible versatility, allowing you to install Huck fasteners from practically anywhere. Like air tools, battery-powered tools are basically point-and-shoot. Pros: Mobility, speed. Cons: Batteries have limited charge before needing to be plugged in again, cost.

Rivet Guns, air + cordless

These guns are suitable for the installation of both structural and standard rivets, i.e. they do not install pin and collar Huck Bolts. They do not require a separate nose assembly and are generally an economical alternative to a Huck guns.

Air Rivet Guns: For frequent rivet installation, an air-powered riveter is the easiest choice for the job. Air rivet guns offer fast installations with consistent results. Some of the pros include: Easy to use, economical (cost saving compared to cordless), and no physical exertion required. They will also install to a set pressure / stroke. Cons: Requires an air source such as a compressor, possibly limiting mobility and making remote use impractical.

Cordless Battery Rivet Guns: Cordless structural rivet guns run on battery power and provide incredible versatility, allowing you to install rivets from practically anywhere. Like air tools, battery-powered tools are basically point-and-shoot. Pros: Mobility, speed. Cons: Batteries have limited charge before needing to be plugged in again, cost.

Manual Structural Rivet tools

For the occasional installation of structural rivets, a hand tool is your most cost-effective option. They work by adding the rivet to the end of the tool, squeezing the handles, and retracting the tool from the now applied rivet. Some of the pros include: Inexpensive, easy to use, great for the handy person. Cons: They require physical force.

What are the advantages of Huck structural rivets?

Huck structural rivets are renowned for their strength and are the superior option compared to most other fasteners, key advantages include:

- One side assembly for fast installations as access to the rear is not required.

- Super strong, forming a mechanically activated permanent joining solution.

- Vibration and weather resistant. Offering high shear & tensile strength.

- Easy to use air, cordless, air and manual tools that are rugged & robust.

- Design flexibility, wide range of types, material, etc. to suit most applications.

- Easy inspection and maintenance, no expensive equipment for quality control.

What's the difference between Monobolt® & Magna-Lok®?

These are popular brands of structural rivets that have many physical similarities, in rivet testing facilities the MagnaLok® outlasted the Monobolt® 20 to 1. Another key difference is Magna-Lok does not require a special nose tip to be installed correctly, unlike the Monobolt® which requires a special nose tip. Huck’s locking mechanism has been engineered into the rivet to eliminate tooling and operator error (subject to using the correct installation gun). Read more about Magna-Lok rivet lab differences.

How do I select the right Huck rivet?

When considering selection you will need to look at; materials, diameter (size), grip range, head style, and strength. Here we look into the important criteria to consider prior to making a final decision.

Huck Rivet Materials.

Ensure the rivet material is compatible with the material being joined to avoid galvanic corrosion. As a rule, avoid using aluminium and stainless steel together, we recommend keeping the metal material like for like for maximum life. Stainless with stainless, aluminium with aluminium, etc.

| RIVET TYPE | MATERIAL | |||

| ALUMINIUM | STEEL | STAINLESS | ||

| ALUMINIUM | ✓ |

|

x | |

| STEEL | x | ✓ | x | |

| COPPER | x | x | ✓ | |

| STAINLESS |

|

|

✓ | |

* Above table is a guide only

✓ Compatible

x Incompatible, must not be in contact

Compatible in rural & mild environments (some corrossion may occur in marine/industrial environments. Painting both metals will reduce reaction)

Huck Rivet Diameter & Hole Sizes.

Huck structural rivet diameter is guided by the material thickness, for instance use small diameter Huck rivets for lightweight application and larger diameter rivets in heavy duty fabrication. The larger the diameter the stronger the rivet, as a general rule the rivet diameter should be about three times the thickness of the thickest piece of joined material.

The size of the rivet diameter & the drill hole size is critical for success. If the rivets diameter is too small for its hole, then the gap may cause installation failure. Referring to the hole diameters before drilling is an easy way to avoid issues later, as a general rule the hole size should be 0.2-0.5MM greater that the rivet diameter. Our product data sheets have detailed information.

Huck Rivet Sizes (metric & imperial).

Huck rivet "Magna-Lok" is available in 4.8MM, 6.4MM, 9.5MM & 12.7MM. T

| HUCK RIVETS | |

|---|---|

| METRIC SIZE | IMPERIAL SIZE |

| 4.8mm | 3/16" |

| 6.4mm | 1/4" |

| 9.5mm | 3/8" |

| 12.7mm | 1/2" |

Rivet Material Grip Range.

The material grip range refers to the material thickness or the depth the rivet can be effectively installed. For example, if two 1.5 mm plates/items need to be riveted, a blind rivet with a material grip range between 2- 5 mm is required. Best practice dictates that the middle grip range of a rivet should be used and not the minimum/maximum sizes. This assists in achieving correct shear and tensile strength whilst ensuring the longevity of the rivet. Please note that the grip range is not the length of the rivet as many people mistakenly believe the length is the amount of material the rivet will pull up.

Magna-Lok® Rivet Head Type.

The rivet head type assists in holding the material together and enhancing its appearances. Dome heads sit proudly above the material, whilst large flange or truss head is a shallower broader head profile & suited for thin or soft material items like thin steel sheeting. The countersunk option provides a flush neat finish subject to countersinking the hole, allowing the head to sit level with the surrounding material.

Frequently Asked Huck Structural Rivet Questions.

How do I install Huck rivets?

To install a rivet, pre drilling of hole is required. Load rivet’s pin mandrel into rivet gun. Insert rivets body into hole and activate gun. Upon activation the head of the rivet is pushed against the outer surface of the tool, whilst the tool pulls up the central pin (mandrel). As a result, the bottom portion of the rivet compresses, and expands on the blind side. This expansion maxes out when it reaches approximately one and a half times the size of the original diameter. Resulting in a larger surface in which the two materials are effectively fastened together.

How does a Huck rivet work?

Below we illustrate how a rivet works. Essentially a rivet is a metal tube (body) with a pin (mandrel) through it, upon installation the pin's head is shaped to expand the tube & lock up the material as the rivet gun is pulling up the pin.

What is the difference between the pop rivet and blind rivet?

Many people clients ask this question and the short answer is there is no difference. They are two labels for the same item, a blind rivet means you do not need access to the other side of the material, or you can't see the other side of the material. Also known as Pop® rivets because it is the brand name of the original rivet company.

Which is the strongest Huck structural rivet?

Structural rivets are the strongest rivets on the market and Aerobolt has the complete Huck Rivet range including the original multi-grip rivet "Magna-Lok", the Huck Rivet "Magna-Bulb" with its superior strength and the hybrid of the two "Hucklok Rivet". One of the strongest structural rivet option is the the Huck Rivet "Magna-Bulb". For installation values, refer to the table below to compare a range of structural rivet results.

| STRUCTURAL RIVET TYPE -STEEL | KEY LAB METRICS FOR RIVET 6.4 MM (1/4") | |||

| Shear Typ. (kN) | Tensile Typ. (kN) | Grip Range (mm) | ||

| Magna-Lok® (HRDS-0806) | 11.1 | 8.2 | 2.0 – 9.5 | |

| Hucklok® (HKLP-R8-6) | 15.6 | 8.5 | 2.0 – 9.5 | |

| Magna-Bulb® (MBDS-0806) | 16.0 | 8.9 | 5.8 – 7.8 | |

| Allok® (ARDS-08145) | 13.7 | 7.9 | 5.0 – 8.5 | |

Why are Huck rivets used on aeroplanes?

Rivets are the preferred choice of fasteners in the construction of aeroplanes because they can withstand extreme stress without breaking, whilst barely succumbing to damage. They are used in aerospace manufacturing because it simplifies both production and the maintenance of the aircraft.

How do you remove a Huck® rivet?

Huck® rivet removal is straight forward with the right tools. This requires the destruction of the rivet, and the best method is to drill it. You will need, a drill, drill bit, long nose pliers, & safety accessories such as glasses and gloves.

Steps: Use your safety glass & gloves before starting the drilling process. Place the drill bit against the rivets’ center pin and drill through the body at a low but steady speed. Once drilling is completed, pull the rivet off with your long nose pliers.

Why have my structural rivets failed?

There are a couple of reasons your rivet has failed. The issue could be a dodgy rivet from a shifty supplier or an installation issue. Either way we offer a wide range of technical services, including rivet testing services. We have teamed up with a NATA approved lab, that undertakes laboratory rivet testing services. Should you have a rivet failure, let us know so we can review your application and or have your rivets sent to the NATA approved lab for laboratory rivet testing.

Do you deliver rivets throughout Australia?

Yes, we can deliver Australia wide through our network team of courier companies. In Sydney we offer our customers same day delivery if you order before 10.00 am or the next day. Deliveries to major cities such as Melbourne, Brisbane including regional South Eastern Australia are either next day delivery or 2 days turnaround.

Why are Huck rivet diameters in imperial measurements?

The USA still use the imperial measurement system. On this website we have presented diameter measurements in both imperial and meteric. For instance the diameter 3/16" is 4.8 mm in metric, or 1/4" is 6.4 mm and 5/16" is 7.9 mm. Providing the two measurements is important as the drill hole is critical to the success of the installation. To convert imperial to metric, click here.

Who makes Huck rivets?

Huck rivets are manufactured by Huck International Inc. which is now part of Howmet Aerospace Systems.

Magna-Lok Rivet Summary.

Huck Magna-Lok structural rivets offer superior fastening capabilities for heavy-duty fabrication applications. It has become the go-to structural rivet because of its flexiblity with material depth, making it the efficient rivet option. Their versatility means they fit a wider range of material grips so that if the application depth differs the rivet will most probably accommodate the change. In numerous applications instead of having many different structural rivets you will find one Magna-Lok® rivet will be preferable; resulting in considerable cost and time savings plus reducing the chance of using an incorrect rivet.

Aerobolt is the award-winning go-to wholesaler of standard rivets , structural rivets, Huck bolts, nutserts, rivnuts, adhesives & power tools, like nutsert tools and rivet guns including some popular cordless options.

Proudly, we are Australia's number one Huck Distributor of genuine Huck bolts and structural rivets plus the sale, service and hire of Huck guns and hydraulic power rigs.

Committed to providing a total supply solution with a great customer service focus, your one-stop shop for technical know-how, supply of goods & tool hire through to the servicing of your equipment. So for all your fabrication supply requirements - call us on 02 9755 3747 or contact us.

Copyright © 2025 Aerobolt Australia Pty Ltd. All rights reserved.